OILPATH Adjustable Priority Flow Control Valve 60 or 114 Lt/Min 3,000 psi

OILPATH (Australia) Hydraulic Priority Oil Flow Control Valves,

Available in Two sizes with and with out Adjustable relief valve.

1/2" BSPP Ports Controls oil flows from 0-60 Litres per Minute

3/4" BSPP ports Controls Flows From 0 to 114 Litres per Minute

Pressures up to 3,000 psi (200 bar).

Product Overview: With this valve you can basically manually divide and adjust one oil flow into two,

and then prioritise a certain amount of oil flow to one function called the the CF or Control Flow,

the valve will automatically adjust to maintain a steady flow rate, even with pressure fluctuations.

The Excess Flow leaving the second EX port: can be used to supply oil to another valve or function or can be returned to Tank.

The Priority Flow Control Valve keeps things running smoothly.

Have you ever had one oil flow supply in a hydraulic system with two jobs to do?

Well, the Adjustable Priority Flow Control Valve will help you to manage the fluid flow between them.

Examples of Uses of Adjustable Priority Flow Control Valves:

The Marine Industry: - we have used an Adjustable Priority Flow Control on Fishing Trawlers for Multiple Winch Control.

A large winch is used to haul in heavy nets and a secondary line winch or anchor Winch. The valve prioritised the higher pressure flow to the heavy net winch motor, ensuring enough power to operate even under heavy loads.

The advantage of the adjustable lever: is that you can as required adjust the flow and the resulting operating speed between the primary and secondary functions. Once the controlled flow is set, it will remain nearly constant with variations in pressure on either the controlled or excess flow ports. In Other words, you can set the lever and the flows to each function and then get back to the the real task at hand, Hauling Fish or Crabs or Hauling an Anchor.

Earthmoving Industry - Excavator Arm Control: On smaller lighter custom-built excavators built for underground Opal or Precious metal Mining work. The use of smaller and lighter "remotely powered hydraulics with limited oil flows".

An adjustable priority flow control valve is used to prioritise the flow to the joystick control valves. The operator can adjust the lever arm on the priority flow control to provide flow for faster, digging motions, or faster Track Drives for rapid movement and the excess flow can be directed to other excavator functions, like a Boom Swing, Blade or Rock breaker functions.

The adjustability of the valve allows the operator to prioritise the flow based on their specific requirements at the time, for examle fast digging movements, fast Travel or to prioritise flow to the rock breaker or drilling attachments, all while still being able to control other excavator functions with the remaining flow.

On Mobile equipment with Hydraulic Steering: Priority Flow controls are used to ensure that the powering steering always gets the minimum allowable flow to always ensure that the important steering function gets the "priority" flow it needs for safe reliable operation, while all other essential functions still have enough excess flow to work as well.

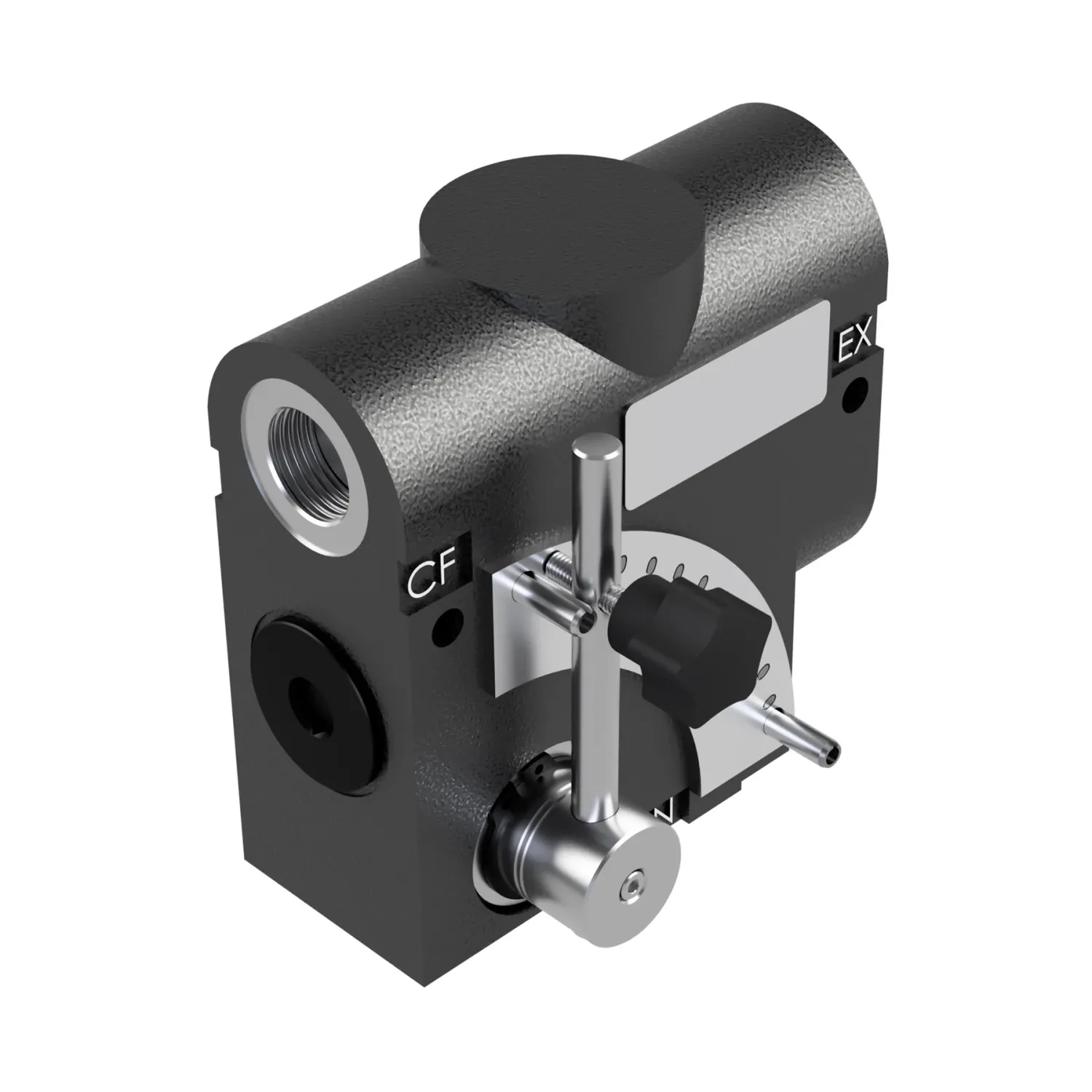

Important parts and Functions of Adjustable Priority Flow Control Valves:

The Control Lever: This acts like a handle on a tap. You adjust it to set the amount of fluid going to the more important function (controlled flow).

Variable Orifice: This is like the opening in the tap. As you turn the lever, the orifice gets bigger or smaller, letting more or less fluid through for the controlled function.

Excess Flow: Any remaining fluid that doesn't go to the controlled function gets diverted here. You can use this excess flow for another less important function or send it back to the tank.

The OILPATH (Australia) Model OP51FC, and OP51FCR: is a pressure compensated, swing arm type adjustable flow control valve.

By swinging the Spool's arm thru a 90° arc, the flow out of the CF or (Controlled Flow) port can be varied within the range given in the Flow specification

of 0-60 Lt/Min for the OP51FC-0.5

and 0 -114 Lt/Min for the OP51FC-0.75 .

Any remaining flow is bypassed to the EX or (Excess) flow port. The EX flow can also be used to power another circuit or can be returned to tank. Once the controlled flow is set, it will remain nearly constant with variations in pressure on either the controlled or excess flow ports.

Please note! if during operation the controlled flow port is blocked, then the valve will compensate in such a manner that there will also be no flow at the EX or excess flow port.

With no relief valve to protect the flow in the circuit upstream, pump failure and or component damage will occur.

If this is a situation that could occur then it is recommended to fit an extra relief valve upstream

or use the model OILPATH OP51FCR that is fitted with a built in Relief Valve.

• PLEASE NOTE The valve model FCR51 has a built-in adjustable pressure relief.

For this model, the excess flow port, labelled (EX) must be connected to the tank.

Steps may be required to keep system oil temperature from getting too HOT.

- Rated Flow: OP51FC-0.5 and OP51FCR-0.5 = 0-60 Litres per Minute

- Rated Flow OP51FC-0.75 and OP51FCR-0.75 = 0-114 Litres per Minute

- Maximum Working Pressure: 210 bar (3000 psi)

- Ports: OP51FC-0.5 = 1/2"inch BSPP

- Ports: OP51FC-0.75 = 3/4" inch BSPP

- Body Material: High Strength Cast Iron

- Spool: Hardened Steel for Wear and Corrosion Resistance

- Seals: Buna - N (Nitrile NBR)

or call 07 55 631982 or 1300 1 HOSES or email us a question on

By click here to email us

IMPROPER SELECTION, INSTALLATION, IMPLEMENTATION, AND/OR OPERATION BY ANYONE OTHER THAN PERSONS WITH APPROPRIATE TECHNICAL AND MECHANICAL TRAINING CAN RESULT IN DAMAGE TO EQUIPMENT OR PROPERTY, SERIOUS PERSONAL INJURY OR DEATH. PROPER PRECAUTIONS AND SAFETY PROCEDURES SHOULD BE IMPLEMENTED PRIOR TO INSTALLATION AND OPERATION OF EQUIPMENT.

MM 21/01/2025 abc SEO