3,000 psi 415 Volt AC 3 Phase Industrial Hydraulic Power Unit

At Hydraulic.Online, we offer a range of premium-quality, 3-phase electric motor driven hydraulic power units designed to meet diverse commercial , industrial and manufacturing needs.

This range of 3 phase electric Power units all produce 200 bar (3,000 psi ) of pressure in the following flows.

They are available as a D.I.Y assembly or optionally can be ordered assembled ready to go by just adding Oil and connecting up the Electricity.

- 10 Lt/min at 200 Bar (3,000 psi) with 30 Litre tank and Accessories

- 15 Lt/min at 200 Bar (3,000 psi) with 30 Litre tank and Accessories

- 20 Lt/min at 200 Bar (3,000 psi) with 55 Litre tank and Accessories

- 30 Lt/min at 200 Bar (3,000 psi) with 75 Litre tank and Accessories

- 40 Lt/min at 200 Bar (3,000 psi) with 100 Litre tank and Accessories

- 60 Lt/min at 200 Bar (3,000 psi) with 180 Litre tank and Accessories

- 80 Lt/min at 200 Bar (3,000 psi) with 180 Litre tank and Accessories

Included Accessories are as follows:

- 3 phase electric motor, bell housing drive couplings and gear pump.

- Steel Tank, Lid and gasket,

- Pump suction strainer

- Tank top oil distribution manifold with pressure relief valve and 250 bar pressure gauge

- 10 Micron Tank top Oil return filter,

- Filler breather Strainer,

- Level indicator with built in temperature indicator.

The guide below will take you through the essential factors to consider, so that you can be sure that you have selected the best size and performance power unit for your specific application.

The Ground Work for selecting the right hydraulic power unit lies in understanding your system's Flow Rate and Pressure requirements:

- The flow rate determines how fast the hydraulic actuators such as cylinders can extend and retract and how quickly can hydraulic motors can rotate (RPM). Flow Rate is It is measured in litres per minute (Lt/min).

- The required flow rate directly influences the size of the hydraulic pump.

- Pressure is the force required to operate the hydraulic system and is typically measured in bar or pounds per square inch (psi).

- Higher pressures will allow greater forces to be generated by cylinders and more torque from motors, but this will require heavy duty pumps and Larger high power electric drive motors.

- The electric motor’s power must be sufficient to meet the combined requirements of flow and pressure.

- The formula for calculating motor power is: kW = (Flow x Pressure) ÷ (600 x Pump Efficiency)

- For example, a flow rate of 10 Lt/min and pressure of 150 bar would require approximately 3.0 kW when factoring in 85% pump efficiency.

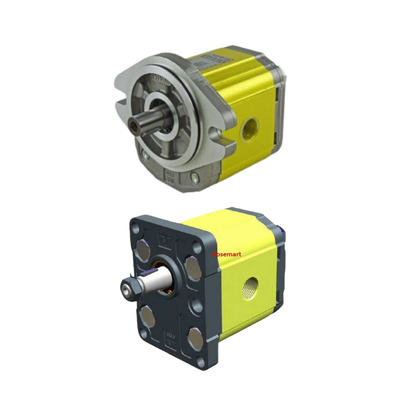

- These are Compact, cost-effective, and reliable.

- Suitable for low-to-moderate pressure applications. From 30 to 200 bar (500 to 3,000 psi)

- All the HPU's in this listing Use Gear Pumps.

- Offer higher efficiency and quieter operation.

- Ideal for applications requiring a consistent smoother flow.

- High efficiency and capable of handling high pressures. From 150 to 420 bar (1,700 to 6,100 psi)

- Suitable for demanding industrial environments.

The pump type should match the performance requirements of your application. For example, a high-flow and high-pressure systems will require piston pumps and heavy duty high efficiency motors with adequate power.

Displacement (cc/rev) = (Flow Rate in Lt/min × 1000) ÷ (RPM of the Electric Motor)

Example 1: 1,400 RPM Motor

- Required Flow Rate: 20 Lt/min

- Motor RPM: 1,400

Calculation: Displacement = (20 × 1,000) ÷ 1,400 = 14.3 cc/rev

In this case, a pump with a displacement of approximately 14.3 cc/rev would be suitable.

- Required Flow Rate: 20 Lt/min

- Motor RPM: 2,800

Calculation: Displacement = (20 × 1,000) ÷ 2,800 = 7.1 cc/rev

For this system, a pump with a displacement of around 7.1 cc/rev is ideal.

- Ensure the selected pump displacement aligns with your system’s pressure requirements.

- Higher RPM motors typically require pumps with smaller displacements to achieve the same flow rate.

- Please also be aware that all pumps have an optimal speed (maximum and minimum rotation rpm) range and you must not exceed or subceed these speed ranges.

By calculating pump displacement accurately, you can ensure optimal system performance and avoid inefficiencies or equipment damage.

At Hydraulic.Online, we offer customisable hydraulic power units tailored to your exact specifications. Choose from a variety of tank sizes, motor capacities, and pump configurations to meet your specific needs.

The tank is a critical component of the hydraulic power unit. It stores hydraulic oil and plays an essential role in maintaining system performance:

1. Oil Storage:

- The tank should have enough capacity to prevent the oil level from dropping too low, which can cause cavitation and damage to the pump.

- As a general rule, the tank capacity should be 2-3 times the flow rate in Lt/min to ensure adequate oil storage.

For example a hydraulic Power Unit delivering 40 Lt/min would require a tank of between 80 to 120 Litres in capacity.

Hydraulic systems generate heat during operation. A larger tank provides more surface area for heat dissipation, helping to maintain optimal oil temperature.

3.Tank Options:

We offer tanks in various sizes and materials to suit different system requirements, ranging from compact units to large-capacity reservoirs.

A well-designed hydraulic power unit includes several auxiliary components to enhance performance and ensure reliability:

- Installed on the tank lid and returning oil into the tank cavity they filter out contaminants from the returning oil.

- By Maintaining oil cleanliness, we are extending the lifespan of all the hydraulic system's components.

- Filler breathers allow the tank to breath clean filtered air and also ensure an even pressure is maintained inside the tank.

- Protect the pump by filtering oil before it enters the system.

- This will reduce the risk of pump damage caused by debris or contaminants.

- Indicators Provide real-time monitoring of oil levels and temperature.

- These help prevent overheating or low oil conditions that could harm the system.

- Gauges display system pressure for easy system monitoring and or troubleshooting.

- They also allow quick adjustments to be made to maintain optimal Hydraulic power unit performance.

- Single-Phase vs. Three-Phase Motors:

- Single-phase motors are suitable for smaller lower flow or pressure applications, and in less demanding systems or areas without access to three-phase power. Typically industrial Single Phase motors typically max out at around 4 kW.

- Three-phase motors are more efficient and powerful and available in a broad range of power outputs (from 1.1 to 300 KW), thus making them ideal for industrial applications requiring higher performance in the form of flow and pressure.

- System Compatibility:

- Ensure that all components, including hoses, fittings, and actuators, are compatible with the power unit’s flow and pressure ratings.

- Customisation Options:

- At Hydraulic.Online, we offer customisable hydraulic power units tailored to your exact specifications. Choose from a variety of tank sizes, motor capacities, and pump configurations to meet your specific needs.

Our hydraulic power units are engineered for reliability, efficiency, and ease of maintenance. By selecting the right combination of components and options, you can achieve peak performance and extend the life of your hydraulic system.

Check out our wide range of industrial-grade hydraulic power units and let our expert team assist you in making the right choice.

Invest in a hydraulic power unit that delivers the performance and durability you need. Contact us today to learn more!

Use the Chart below to help you calculate the the Electric Motor power Requirement To Drive a a Hydraulic Pump to achieve your desired flow and pressure.

The chart below is based on the formula

kW = Lt/min x Bar

612 x Efficiency

This chart assumes a pump efficiency of 85%

| Flow Lt / min |

30 BAR | 40 BAR | 50 BAR | 60 BAR | 70 BAR | 80 BAR | 90 BAR | 100 BAR | 125 BAR | 150 BAR | 175 BAR | 200 BAR | 225 BAR | 250 BAR |

| 1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 |

| 2 | 0.1 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 |

| 3 | 0.2 | 0.2 | 0.3 | 0.3 | 0.4 | 0.5 | 0.5 | 0.6 | 0.7 | 0.9 | 1 | 1.2 | 1.3 | 1.4 |

| 4 | 0.2 | 0.3 | 0.4 | 0.5 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1.2 | 1.3 | 1.5 | 1.7 | 1.9 |

| 5 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 1.2 | 1.4 | 1.7 | 1.9 | 2.1 | 2.4 |

| 6 | 0.3 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 1.2 | 1.4 | 1.7 | 2 | 2.3 | 2.6 | 2.9 |

| 7 | 0.4 | 0.5 | 0.7 | 0.8 | 0.9 | 1.1 | 1.2 | 1.3 | 1.7 | 2 | 2.4 | 2.7 | 3 | 3.4 |

| 8 | 0.5 | 0.6 | 0.8 | 0.9 | 1.1 | 1.2 | 1.4 | 1.5 | 1.9 | 2.3 | 2.7 | 3.1 | 3.4 | 3.8 |

| 9 | 0.5 | 0.7 | 0.9 | 1 | 1.2 | 1.4 | 1.6 | 1.7 | 2.2 | 2.6 | 3 | 3.5 | 3.9 | 4.3 |

| 10 | 0.6 | 0.8 | 1 | 1.2 | 1.3 | 1.5 | 1.7 | 1.9 | 2.4 | 2.9 | 3.4 | 3.8 | 4.3 | 4.8 |

| 11 | 0.6 | 0.8 | 1.1 | 1.3 | 1.5 | 1.7 | 1.9 | 2.1 | 2.6 | 3.2 | 3.7 | 4.2 | 4.8 | 5.3 |

| 12 | 0.7 | 0.9 | 1.2 | 1.4 | 1.6 | 1.8 | 2.1 | 2.3 | 2.9 | 3.5 | 4 | 4.6 | 5.2 | 5.8 |

| 13 | 0.7 | 1 | 1.2 | 1.5 | 1.7 | 2 | 2.2 | 2.5 | 3.1 | 3.7 | 4.4 | 5 | 5.6 | 6.3 |

| 14 | 0.8 | 1.1 | 1.3 | 1.6 | 1.9 | 2.2 | 2.4 | 2.7 | 3.4 | 4 | 4.7 | 5.4 | 6.1 | 6.7 |

| 15 | 0.9 | 1.2 | 1.4 | 1.7 | 2 | 2.3 | 2.6 | 2.9 | 3.6 | 4.3 | 5 | 5.8 | 6.5 | 7.2 |

| 20 | 1.2 | 1.5 | 1.9 | 2.3 | 2.7 | 3.1 | 3.5 | 3.8 | 4.8 | 5.8 | 6.7 | 7.7 | 8.7 | 9.6 |

| 25 | 1.4 | 1.9 | 2.4 | 2.9 | 3.4 | 3.8 | 4.3 | 4.8 | 6 | 7.2 | 8.4 | 9.6 | 10.8 | 12 |

| 30 | 1.7 | 2.3 | 2.9 | 3.5 | 4 | 4.6 | 5.2 | 5.8 | 7.2 | 8.7 | 10.1 | 11.5 | 13 | 14.4 |

| 35 | 2 | 2.7 | 3.4 | 4 | 4.7 | 5.4 | 6.1 | 6.7 | 8.4 | 10.1 | 11.8 | 13.5 | 15.1 | 16.8 |

| 40 | 2.3 | 3.1 | 3.8 | 4.6 | 5.4 | 6.2 | 7 | 7.7 | 9.6 | 11.5 | 13.5 | 15.4 | 17.3 | 19.2 |

| 50 | 2.9 | 3.8 | 4.8 | 5.8 | 6.7 | 7.7 | 8.7 | 9.6 | 12 | 14.4 | 16.8 | 19.2 | 21.6 | 24 |

| 60 | 3.5 | 4.6 | 5.8 | 6.9 | 8.1 | 9.2 | 10.4 | 11.5 | 14.4 | 17.3 | 20.2 | 23.1 | 26 | 28.8 |

| 70 | 4 | 5.4 | 6.7 | 8.1 | 9.4 | 10.8 | 12.1 | 13.5 | 16.8 | 20.2 | 23.5 | 26.9 | 30.3 | 33.6 |

| 80 | 4.6 | 6.2 | 7.7 | 9.2 | 10.8 | 12.3 | 13.8 | 15.4 | 19.2 | 23.1 | 26.9 | 30.8 | 34.6 | 38.4 |

| 90 | 5.2 | 6.9 | 8.7 | 10.4 | 12.1 | 13.8 | 15.6 | 17.3 | 21.6 | 26 | 30.3 | 34.6 | 38.9 | 43.3 |

| 100 | 5.8 | 7.7 | 9.6 | 11.5 | 13.5 | 15.4 | 17.3 | 19.2 | 24 | 28.8 | 33.6 | 38.4 | 43.3 | 48.1 |

MM 28/01/2025 all New