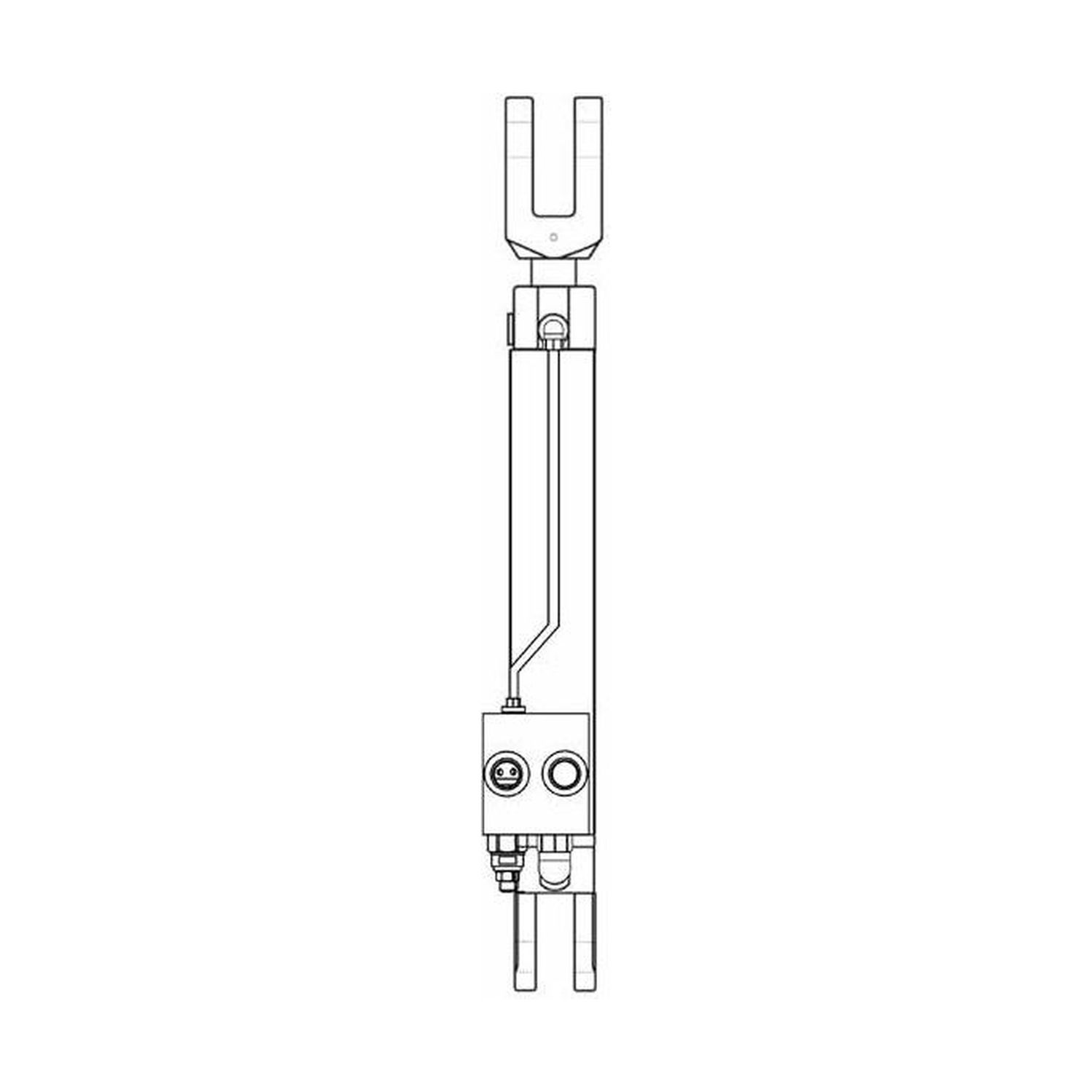

Hydraulic Cylinder Counterbalance Valve, Pipe and Adaptor Kit

Single or Double Counterbalance Valve, Pipe and Adaptor kit for our range of Australian Made Hydraulic Cylinders. Available to fit on Cylinders with bores from 1.5 to 5" and Strokes from a minimum of 10" inches to a Maximum of 48" inches.

If You are Purchasing one or More of Our Australian Made Hydraulic Cylinders with a bore between 1.5 and 5" inches and a stroke from 10 to 48" inches and you feel that the added safety and Control that a single or Double Counterbalance Valve will provide is a great investment.

If you are looking for a cheaper and simpler option try our

Hydraulic Cylinder Pilot Check Valve, Pipe and Adaptor Kit

- Enhanced Safety: Protect your personnel and equipment from hazardous load drops especially during a hose burst situation.

- Improved Performance: Achieve accurate and stable positioning, and smooth, controlled movements.

- Increased Reliability: Prevent damage from cavitation and maintain cylinder position over time.

- Large Range of Solutions: Essential for a wide range of applications involving suspended or overrunning loads.

1. Cylinder Bore Size: Select from the drop down menu if your cylinder has a 1.5" or is a 2" "short" Cylinder, or if it has a bore diameter between 2" and 5" inches. The Default selection is (2" - 5" (Standard) length Cylinders)

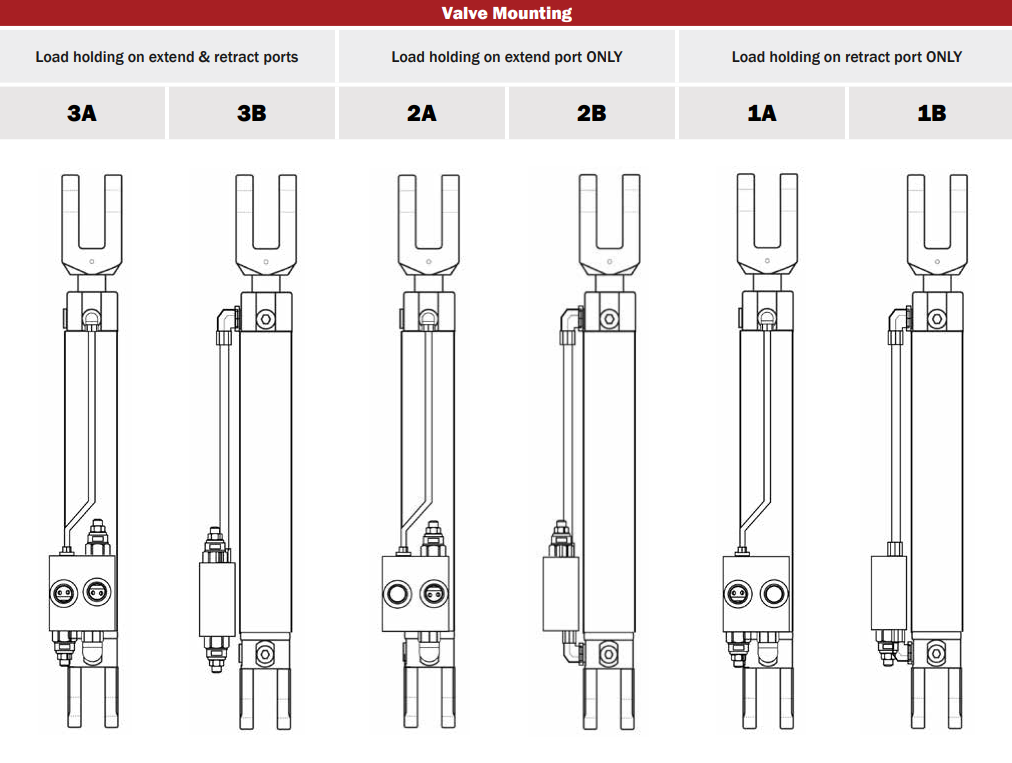

2. Load Holding On (which cylinder port): Select from the Drop down Menu, whether you want Load Holding on the Cylinder's, Retract Port, Extend Port or on the Retract and Extend Ports. (Please see Image below).

3. Valve Mounting Position: Select from the Drop Down Menu whether you want the Counterbalance Valve Mounted on the Cylinder' A port or B port. (Please see Image below).

4. Cylinder Stroke: Select from the Drop Down Menu the Stroke of your Cylinder in inches.(Please note minimum Cylinder Stroke is 10" and a Maximum Stroke is 48" inches)

Plumbing kit (hardline pipes and adaptors and a single or double acting counterbalance to fit our Australian Made AG cylinders.

Please note this is ONLY for our Australia Made Cylinders.

Please Note:

Each valve must be individually set during the commissioning process by the hydraulic fitter

This Kit Does Not Include the Hydraulic Cylinder.

Advantages of Counterbalance Valves:

- Safe Overrunning Load Control: Provides smooth, controlled lowering of heavy loads, preventing dangerous free-fall.

- Eliminates Damaging Cavitation: Maintains back pressure to prevent vacuum formation and extend cylinder lifespan.

- Precision Movement: Improves metering and control for accurate operation, especially with vertical or inclined cylinders.

Reasons for Installing Counterbalance Valves:

Counterbalance valves are more sophisticated than simple load hold valves. They are typically pilot-operated and are specifically designed to control the movement of a cylinder against an overrunning load (a load that tends to pull the cylinder out, like gravity acting on a vertically mounted cylinder extending).

Controlled Descent of Overrunning Loads: Counterbalance valves are essential for safely and smoothly lowering heavy, overrunning loads. They work by creating back pressure on the cylinder's extending port.

Preventing Cavitation: When an overrunning load pulls the cylinder out faster than the pump can supply oil, a vacuum (cavitation) can occur in the cylinder's retracting port. Counterbalance valves, by maintaining back pressure, ensure there's always sufficient oil on the non-load-bearing side of the piston, preventing cavitation and the associated noise, damage, and erratic movement.

Improved Metering and Control: By controlling the flow out of the cylinder, counterbalance valves can improve the overall metering and control of the cylinder's movement, especially when dealing with variable loads or speeds.

System Stability: In applications with large, moving masses, counterbalance valves can contribute to system stability by preventing sudden, uncontrolled movements.

Why Install on Extend and/or Retract Ports?

The decision to install these valves on the extend, retract, or both ports depends entirely on the application and the potential hazards or control requirements:

Counterbalance Valves:

MM / DMc 15/05/2025 variations $ Pic Abc Seo links