Hydraulic Metal Forging KIT 240 V single phase 16 or 25 Tons Force

Complete DIY Metal Forging Hydraulic Press KIT for 240 Volt Single Phase, options for 16 or 25 Tons of Force.

The Ideal KIT for a Home or Garage installation: that has no 3 phase electricity.

Please note: you will require a separate 20 amp supply with matching plug and outlet.

The kit has all the Hydraulic Parts you will need to build your own Hydraulic Metal Forging Press

Kit Includes

Features

- 240 volt, 3.7Kw Single phase Electric Motor,

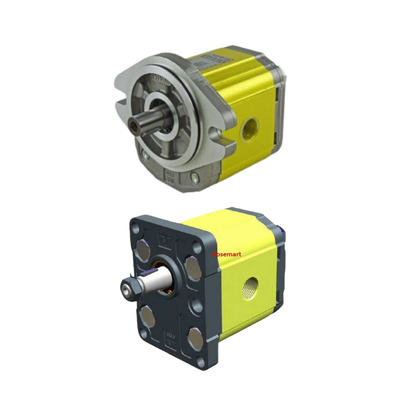

- Automatic 2 stage Hi-Lo Pump,

Hi Lo means that the 2 stage pump automatically changes from

High Flow and Low pressure to Low Flow and High Pressure. - 16 or 25 Ton Big bore (4" or 5") Cylinder,

- 45 Liter Oil Tank,

- Oil Retrun Filter,

- Lever actuated Direction Control Valve,

- DIY High and Low-Pressure Hoses and reusable Hose Fittings,

- Stainless Steel Pressure Gauge

The 240 volt, 3.7Kw metal forge hardware package.

The 3.7 kW motor & hi-lo pump are the maximum power you can run on 240 volts Single Phase.

This setup gives you the maximum speed & tonnage we can provide for 240 volts.

Please Note

We can also supply 3 phase motor for the same cost if required.

Just about all the hydraulic hardware, you will need to build your own metal forge.

the 5" bore cylinder can produce a maximum of 25 tonnes of force, with a good speed (see video of actual unit).

You will need to assemble the parts and design and build your own frame.

The electric motor needs to be wired and you must use a licensed electrician.

as you will need to fit an electric cord into the motor.

There is a wiring diagram under the lid, but by law, an electrician is supposed to fit this.

It is very important to test the rotation before fitting the pump.

Whilst standing behind the motor, please ensure the fan turns clockwise.

Running the pump in the wrong direction will blow its seals and oil will leak out.

You must also have a 20 amp fused / circuit to run this unit.

Please note The pressure relief on the directional flow control valve is factory set to 2200 psi.

Simply adjust with an Allen key up to 3000 psi for maximum tonnage.

The power beyond sleeve in photo is not supplied nor required for this build.

What's included

- 3.7Kw electric motor

- Bell housing, shaft couplers

- A cast iron hydraulic Hi Lo pump

- Lever Actuated Hydraulic Directional Flow Control Valve

- 5" bore, 8" or 12" stroke ram, produces 25 tonnes of force at 3000 psi

- 45 Liter oil tank, 50 x 30 x 26 cm (Length/ Width/ Height)

- Screw on 25 micron Oil Return Filter and Aluminium Filter head

- Hydraulic adapters and fittings to fit Tank, Pump, Valve, Cylinder, Filter

- 8 Meters of 5000 psi 3/8 two hydraulic Hose with Field fit DIY Hose fittings.

- 2 meters of 1/2" 4000psi hose for return to filter with Field fit DIY Hose fittings.

- 3 Meters of 150 PSI Oil Suction Discharge Hose with Super Clamps

- Pressure gauge with hard mount adapters now included (not in photo)

For electric spool positioner options additional wiring and switches are required (not supplied) and allows open/closed signal input only (not proportional/PWV)

What you require;

The electrical connection of the motor, and an on/off switch

Nuts & bolts.

Press Frame etc

Cylinder Speeds (Velocity High and Low Flows)

Using a hydraulic cylinder with a 5" bore

high flow will produce a Down speed of 25 mm per second

and an Up speed of 30 mm per second.

in Low flow, it will produce a

down speed of 4 mm per second

with 25 tons of force

up speed will always be 30 mm per second

The video below is of the actual hardware package in Action (Video with courtesy and thanks to our customer Grant

The cycle time as well as the forces generated will vary depending on the

bore & stroke of the hydraulic ram you are using.

Please contact us with your requirements.

A few examples using 5" bore rams

- With a 12" stroke = 19-sec cycle (full down and up)

- With an 18" stroke = 18 seconds down and 15 seconds up.

A 4" bore ram will be faster.

The pump comes with a 1" suction tail & has a 1/2" BSPT pressure port.

The pump is the highest possible LPM (flow) available for a 10 Hp motor.

As mentioned above, The pump is a hi-lo pump,

which means it pumps High Flow at low Pressures,

this High Flow is used when the cylinder is extending or retracting,

but once your forge hits the job to start the deformation process,

it automatically drops to Low Flow High-Pressure cycle to enable

very high pressing forces with good control.

Again tonnage is dictated by the bore of your chosen ram.

As an indication, you will produce the following tonnages;

4" bore ram = 16 tonnes,

5" bore ram = 25 tonnes.

The larger the bore, the higher the tonnage.

However, the larger bore needs more oil volume, resulting in slower up-down speeds.

This is a professional quality unit, made to perform & last.

We also stock Australian-made hydraulic rams,

1 spool monoblock valves to operate the up-down function for your press.

Please call us for additional parts or larger / smaller units. We can supply 5Hp up to 20hp setups. (07) 5563 1982

MM 14/9/2024 abc SEO